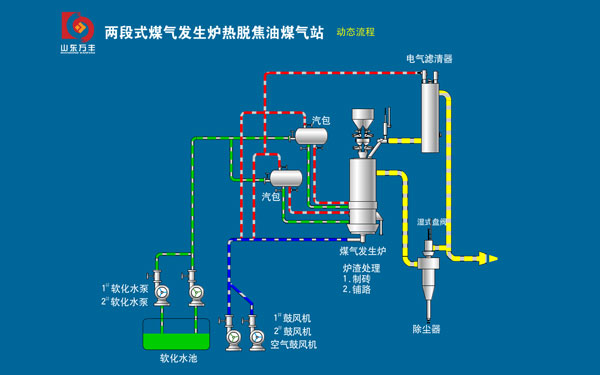

Technological process

Two section type gas generating furnace of gas to air blast of continuous gas: a furnace body water clamping sleeve and phenol water evaporation heat exchanger produced a low-pressure steam and blast air mixture to change the composition of the saturated vapor as gasifying agent (saturation temperature control in 55 to 65 DEG C). From the bottom of the gas furnace, the furnace grate into the gasification furnace, and the heat generated by the heat generated by the reaction of the raw coal and the coal in the gasification section. There are nearly 65 per cent of hot gas after within the center pipe and annular furnace wall channels are derived, forming a bottom gas; rest, about 35% of the hot gas directly on the pyrolysis of bituminous coal heating, drying, carbonization, mixed with dry distillation gas formation top gas.

(1) the production of the top gas

Into the furnace of coal by gasification of hot gas heating first to lose water inside and outside (90 to 150 DEG C), and then gradually by dry distillation (150 to 550 DEG C) prolapse volatile volatile ingredients for tar, alkane gas, phenols and H2, CO2, CO and H2O mixture. Among them, tar, tar light with top gas to enter the follow-up purification was removed, and alkanes and H2, CO2, CO gas carbonization and gasification of occurred gas mixture to become the top gas.

(2) the cooling process of top coal gas purification

Top gas purification treatment process for advanced electrical tar precipitator, between the working temperature for 90 to 150 DEG C, removal of heavy tar (tar calorific value up to 82 kcal / kg and above), the yield for different kinds of coal and not, generally 2 to 3.5% of the total furnace coal, high-quality chemical raw materials or fuel.

(3) the production of bottom gas

The raw coal was at the bottom of gas carbonization in carbonization zone, formation of semi coke gasification into heat. The volatile components of hot semi coke are generally from 3 to 5%. Semi hot coke due to take off his coal in the active component and gasification activity than bituminous coal is decreased, the gasification intensity is generally up to 270 ~ 350Kg / square meters., two-stage gasifier fire layer temperature is generally 1000 ~ 1300 DEG C. Hot semi coke with steam or air mixture occurs the following reaction:

C+O2=CO2+408840 thousand Jiao / thousand

C+1/2O2=CO+123217 thousand Jiao / thousand

CO2+C=2CO-162405 thousand Jiao / thousand

H2O =CO+ H2-118821 C+.

2H2O =CO2+ 2H2-75237 C+.

Bottom gas is completely gasification gas, almost no tar. But with a small amount of dust, the calorific value is generally 1200 to 1300 kcal /Nm3. According to the principle of gasification, high temperature fire layer thickness, gas calorific value also increased, and vice versa.

(4) the purification process of bottom gas

The bottom gas enters the cyclone dust collector and the temperature is about 450 ~ 550.